Chapter 21 Welder Certification. Daing 438 Pec icaf 37.

Engineering Drawing And Design Chapter 18 Welding Drawings Ppt Video Online Download

Arrow side single bevel groove weld d.

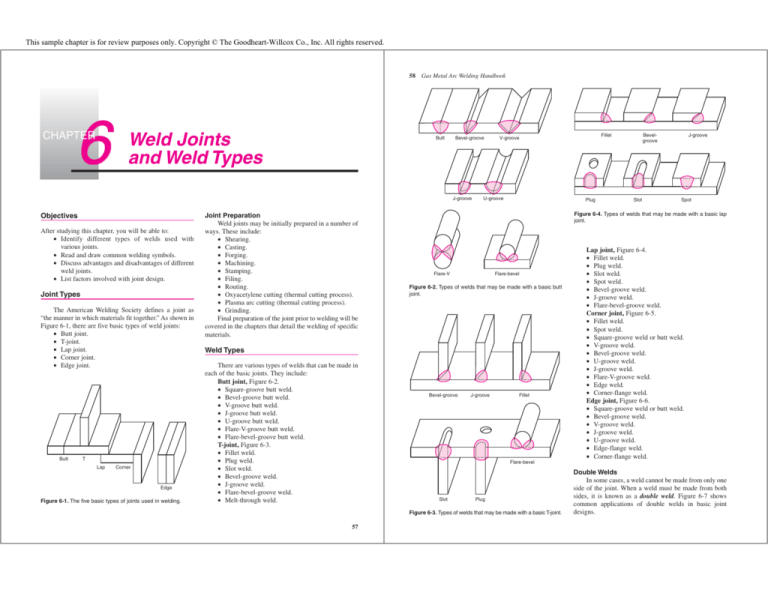

. A weld joint with a bevel depth of ½ d. Groove Welding Symbols 45 8. Plug and slot welds Other types of welds include.

Further it reveals making the learning process to weld a rewarding and interesting. Process and Method 83 12. Our specialties include the welding and fitting of beams plates or columns.

CHAPTER 4 Weld Joint Geometry and Welding Symbols Contents Introduction 4. The leg dimension from one segment to the next is the same and each weld increment is the same length as the next around all the nooks and crannies of the joint without interruption. This weld is an extremely common practice in fabrication and field work.

Welding Symbols After completing this chapter you will be able to. A type of welding that is generally limited to thin materials high-integrity joints or small parts because of its low welding speed and high cost of equipment and materials. Basic Types of Welds.

Identify the following welding symbol below. See reviews photos directions phone numbers and more for Jobco Welding Fabrication locations in. What is an intermittent fillet weld.

How is the size of a fillet weld shown on a welding symbol. See reviews photos directions phone numbers and more for Whiteys Welding Fabrication locations in. Interpreting metal fab drawings.

7 Welding Joint Design Welding Symbols and Fabrication. Arc spot and seam welds Edge welds Flange welds Surfacing welds Seal welds. Chapter 23 Welding Metallurgy.

Start studying Chapter 17 - Welding Joint Design Welding Symbols and Fabrications. So in essence the intermittent welding symbol implies the weld is continuous the size does not vary ie. Basics of Welding Symbols 21 5.

Montclair NJ - JDC Welding based in NJ specializes in the welding fabrication of structural steel in Montclair. Learn vocabulary terms and more with flashcards games and other study tools. Spot Seam Stud Welding Symbols 67 10.

Cut drilled or welded in Montclair. This symbol is characterized by a right triangle which is the lateral shape of a real fillet weld. Pipe Drawings 92.

ButtThis is a joint where two plates are butted together edge to edge. Chapter 22 Welding Joint Design and Welding Symbols 36. Welding Principles and Applications Fifth Edition Larry Jeffus Australia Canada Mexico Singapore Spain United Kingdom United States.

Cut drilled or welded in Matawan. A T joint is a joint where two metal plates are at a 90 degree angle and one of the pieces connects away from the edge. Our company provides all services necessary for your complete construction or Montclair home-addition needs.

A weld joint with a taper depth of ¼. Chapter 17 Gas Tungsten Arc welding of Pipe. Other side single bevel groove weld.

Chapter 24 Weld ability of Metals. The composition of welding symbols for fillet welds is governed by a number of explicit rules. Double bevel groove weld c.

Sketch the five basic welding joints Explain the factors that must be considered when choosing a weld joint design Discuss the factors to consider when selecting a weld joint design List and explain the information that can be included on a welding symbol Sketch a welding symbol and. Chapter 18 Welding Joint Design Welding Symbols and Fabrication. Fillet Weld Symbols 33 7.

After completing this chapter the student should be able to solve basic welding fabrication math problems. Sketch the five basic welding joints Explain the factors that must be considered when choosing a weld joint design Discuss the factors to consider when selecting a weld joint design List and explain the information that can be included on a welding symbol Sketch a welding symbol and. Chapter 22 Railroad Welding.

It is authored by Larry Jeffus. The welded joint will occur at the edge of the top plate. There are three basic types of welds.

Chapter 20 Testing and Inspection of Welds. The book explains all about developing skills to become a highly paid versatile welder. Intermittent fillet welds may be used to carry calculated stress.

Welding symbols and their components are created using the same units the drawing in which they are displayed. What is the main purpose of the root face. Reduce fractions and decimal fractions.

Chapter 19 Welding Codes Standards and Costs. A lap joint is where one plate lays on top of another plate. Welding and Metal Fabrication is a superb handbook for welders.

JS11 Joint Design Welding Symbols Student Handout for. Single bevel groove weld b. What information could be provided in the tail of a welding symbol.

For proper application of such welds in welded fabrication these rules require that the following information be shown at designated locations in the welding symbol unless specific general notes covering. A compression force pushes the weld together and tries to crush it. Our company provides all services necessary for your complete construction or Matawan home-addition needs.

Our specialties include the welding and fitting of beams plates or columns. Welding Joint Design and. Welders can improve both the welding and fabrication skills together.

Edge Weld Symbols 77 11. One of the most important welding symbols is the fillet weld. Convert mixed units fractions and decimal fractions.

View Chapter 4 Welding Symbolpdf from PH 123 at Technological University of the Philippines Taguig. Welding Joint Design and. Calculate the area and volume of various geometric shapes create a bill of materials.

Tensile forces pull the weld apart. 1641 New Market Ave South Plainfield NJ 07080. Welding Symbols After completing this chapter you will be able to.

Forces Placed on a Weld. 3181 Symbols of Fillet Welds. Supplementary Welding Symbols 27 6.

Plug Weld symbols 60 9. Matawan NJ - JDC Welding based in NJ specializes in the welding fabrication of structural steel in Matawan. Fillet welds are generally performed on a 90 degree joint of 2 perpendicular pieces of metal.

Interpreting metal fab drawings. Advancing rapidly from basic concepts and processes to todays most complex cutting-edge welding technologies and practices this comprehensive text features valuable information on topics such as welding metallurgy metal fabrication weld testing and inspection joint design job costing and environmental and conservation tips. Pipe Symbols 87 13.

Engineering Drawing And Design Chapter 18 Welding Drawings Ppt Video Online Download

Engineering Drawing And Design Chapter 18 Welding Drawings Ppt Video Online Download

Welding Joint Design And Welding Symbols Ppt Video Online Download

Engineering Drawing And Design Chapter 18 Welding Drawings Ppt Video Online Download

Engineering Drawing And Design Chapter 18 Welding Drawings Ppt Video Online Download

0 comments

Post a Comment